Lead-in

As module sizes increase, material usage has not risen but instead decreased, leading to high breakage rates in projects. How did this happen, and what hidden information lies behind it?

Table of Contents:

Chapter 1: A Startling Revelation

Chapter 2: Fragile Glass

Chapter 3: Single Testing

Chapter 4: Path to Solutions

Chapter 1: A Startling Revelation

On October 20, 2025, the renewable energy podcast channel SunCast posted on LinkedIn, citing test results from independent third-party Kiwa PVEL, revealing a shocking phenomenon.

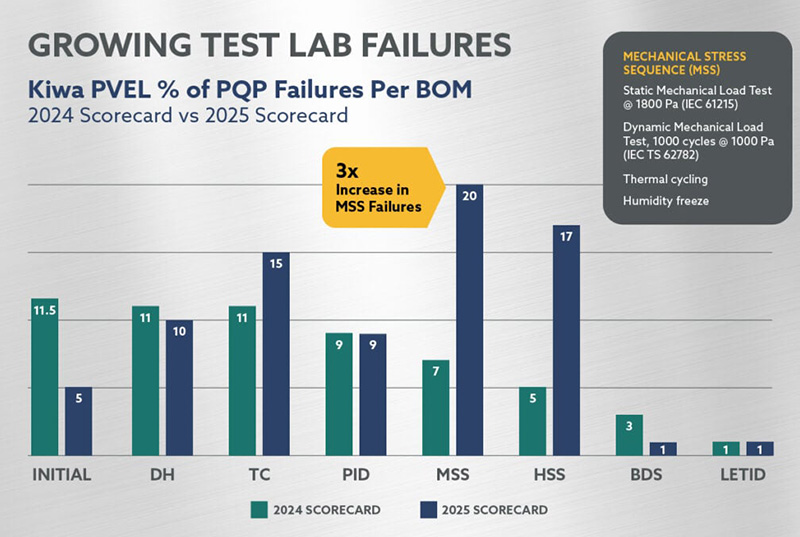

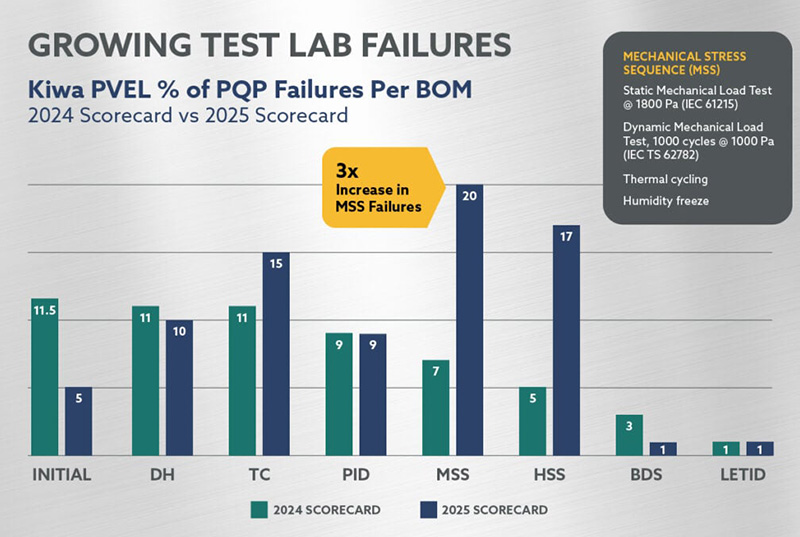

Kiwa conducted mechanical load tests on a large number of modules this year, with 20% failing under a static pressure of 1800 Pa. In contrast, the failure rate in 2024 was only 7%.

▽ A linkedin post on the SunCast podcast

This post quickly gained traction on LinkedIn, sparking debates in the comments section over the validity of the 20% failure rate. However, as more third-party institutions joined the discussion, it became clear that high module breakage rates are widely recognized in the industry.

▽ Mechanical load testing at Kiwa Laboratory

In fact, as early as June this year, Kiwa invited 50 module manufacturers for a comprehensive "health check" of their products. Kiwa also innovatively introduced a "Reliability Scorecard" system to help users accurately assess the performance of different manufacturers’ modules.

The tests were strictly conducted in accordance with IEC 61215 standards, covering static load, dynamic load, hail resistance, and electrical performance. The results showed frequent occurrences of glass breakage, frame tearing, junction box damage, and other issues, with an overall high damage rate of 20%.

▽ MSS(Mechanical Stress Sequence)

The failure rate of mechanical loads is three times that of previous years

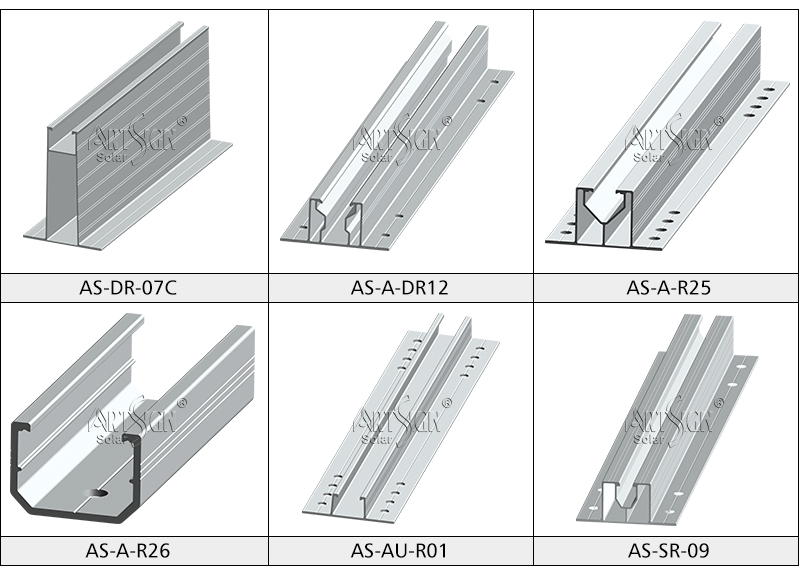

Kiwa’s mechanical load test sequence includes various installation methods, identified by numbers:

- 400mm mounting holes, ±1800 Pa static pressure test

- 790mm mounting holes, ±1800 Pa static pressure test

- Four-corner mounting along the short edge, ±1800 Pa static pressure test

- Dual-rail four-clamp mounting, ±2400 Pa static pressure test

Clearly, these tests are ranked from highest to lowest in terms of mechanical performance requirements. Kiwa uses this numbering system to track which modules pass which tests, allowing users to indirectly judge the mechanical strength of the modules.

Apart from Kiwa, other third-party institutions worldwide have also noted the widespread issue of module breakage in recent years.

In 2022, FUSC (Federal University of Santa Clara) established a 100 kW experimental site in southern Brazil, equipped with bifacial modules on trackers. Within a year, 83 out of 158 modules developed glass cracks, a breakage rate of 52.5%.

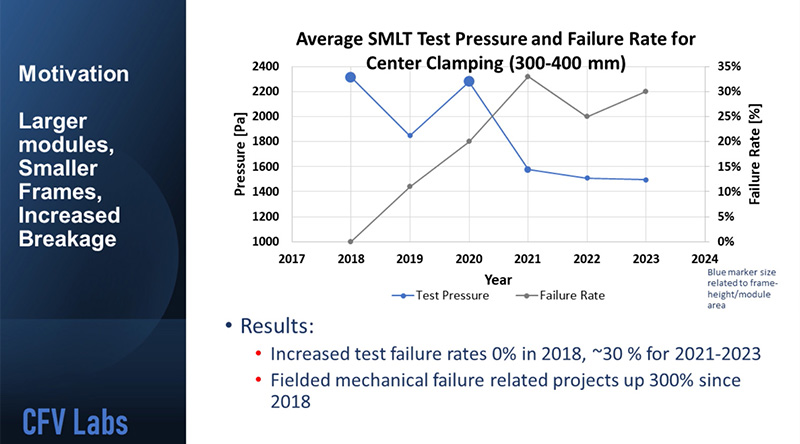

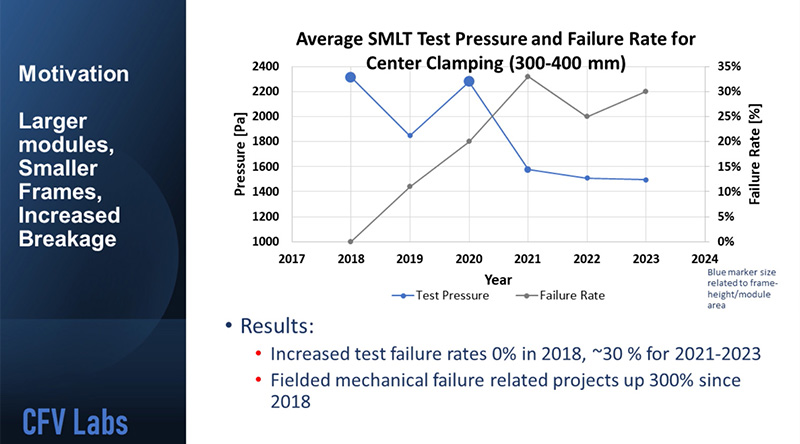

In 2023, CFV Laboratory mentioned in an online exchange that their test data showed module failure rates in 2023 were three times higher than in 2018. Nearly 30% of the modules tested by CFV failed under a test pressure of 1500 Pa.

▽ The pressure resistance of components is decreasing year by year

The failure rate of components is increasing year by year

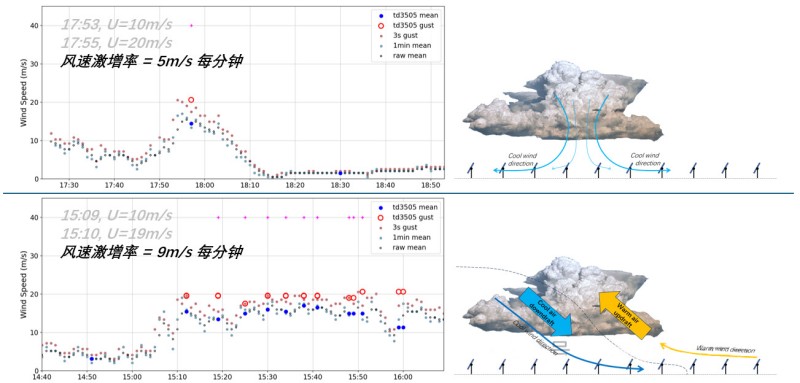

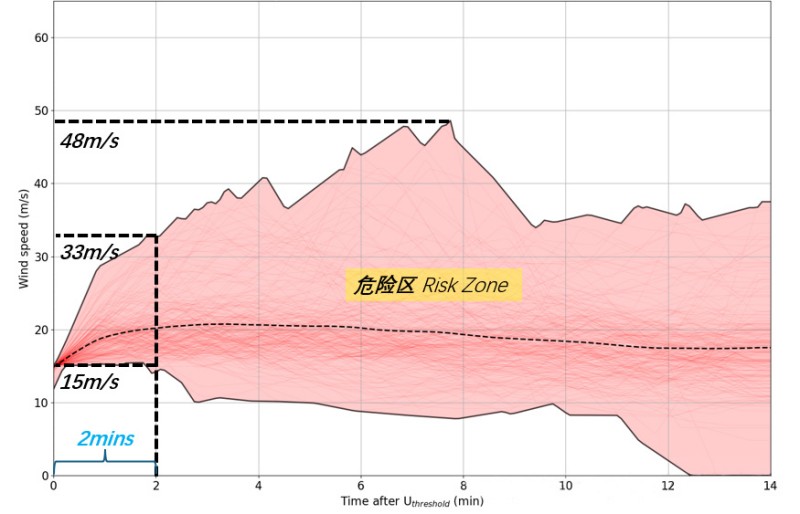

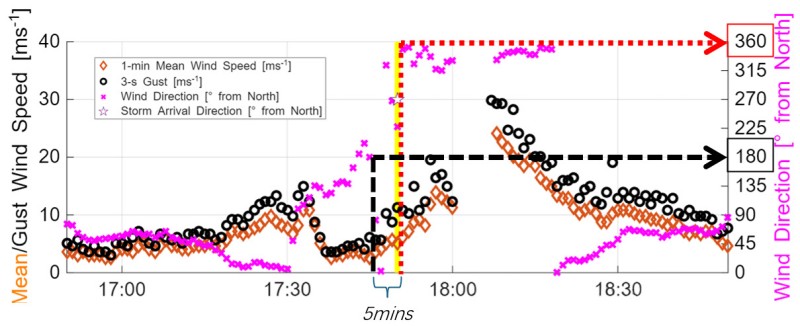

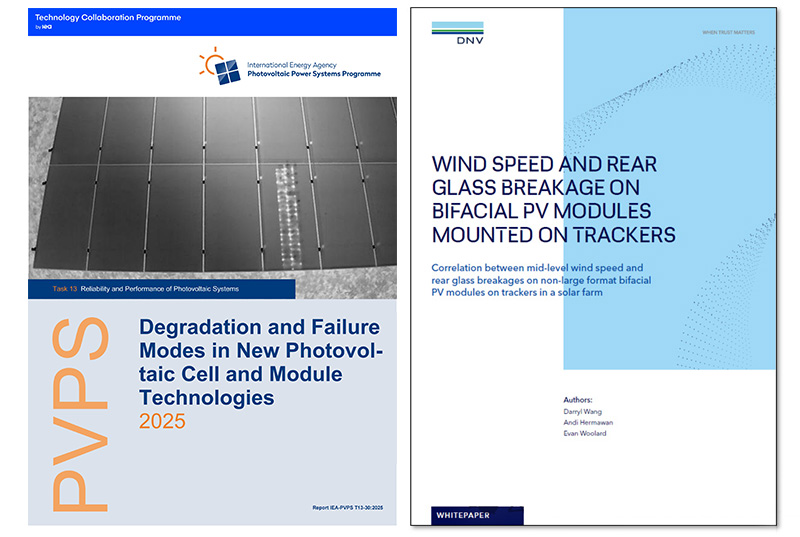

In 2024, DNV published a white paper claiming that in a bifacial module tracker project in the Asia-Pacific region, 15% of the modules’ rear glass broke when wind speeds exceeded 15 m/s.

In February 2025, the IEA PVPS task force released a report on module failure rates, stating that bifacial modules with 2 mm glass could experience rear glass breakage rates of 5–10% within the first two years of installation.

▽ Reports on component damage by PVPS and DNV

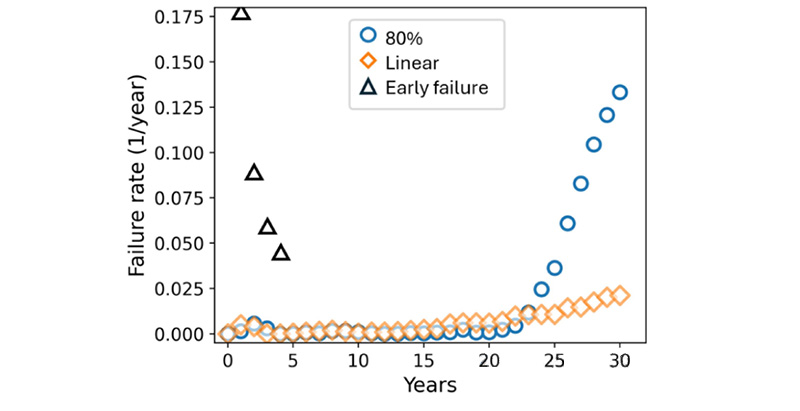

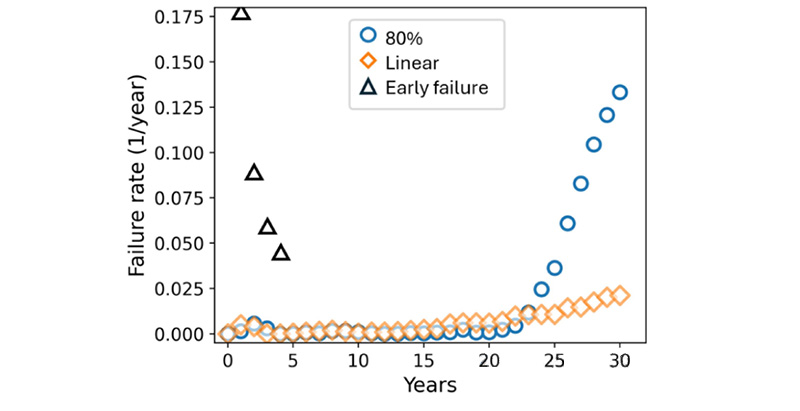

In March 2025, IEEE magazine published an article analyzing the current glass breakage rates of bifacial modules, noting that the first five years of a project represent the peak period for module breakage, with rates as high as 17.5%.

▽ The failure rate of components published in the IEEE Photovoltaic Journal

It seems as if, overnight, once-durable modules have become fragile, which is disheartening.

Chapter 2: Fragile Glass

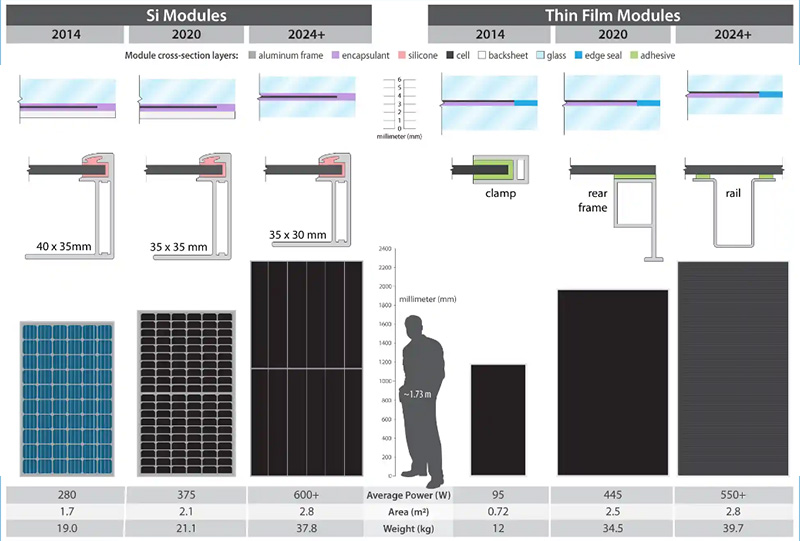

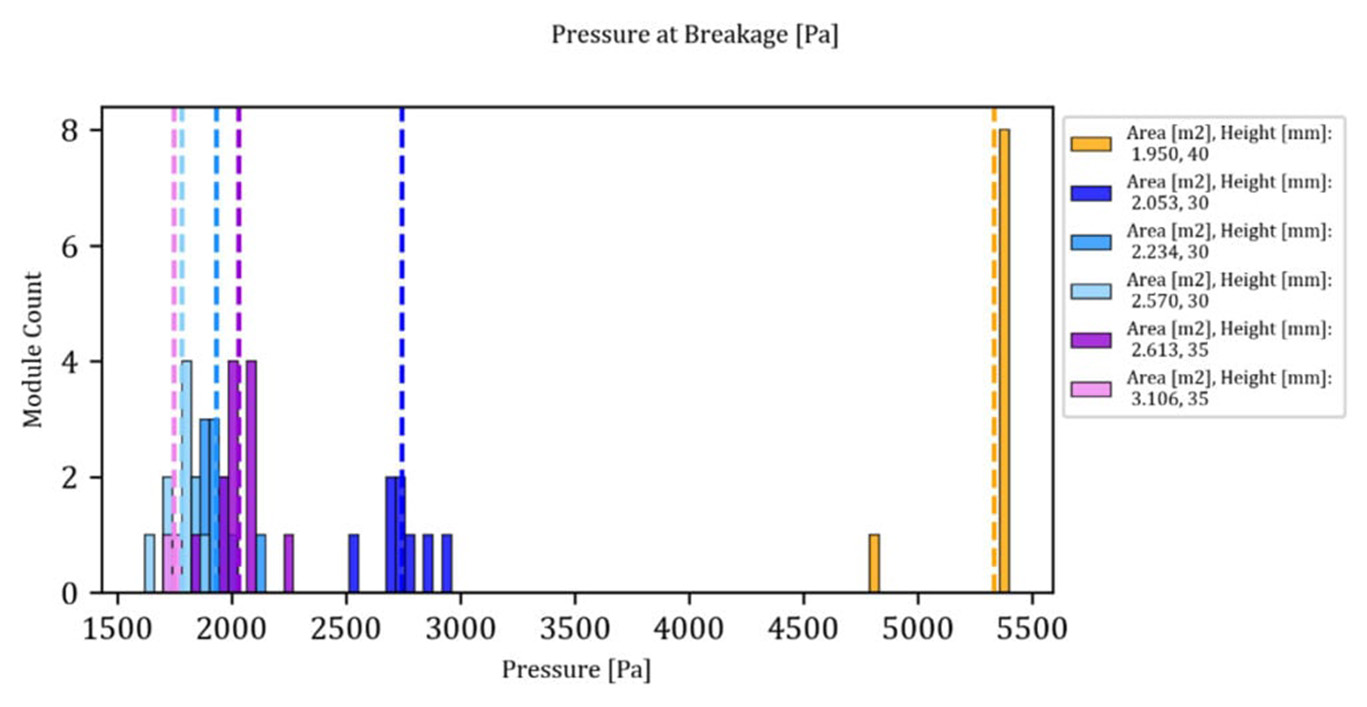

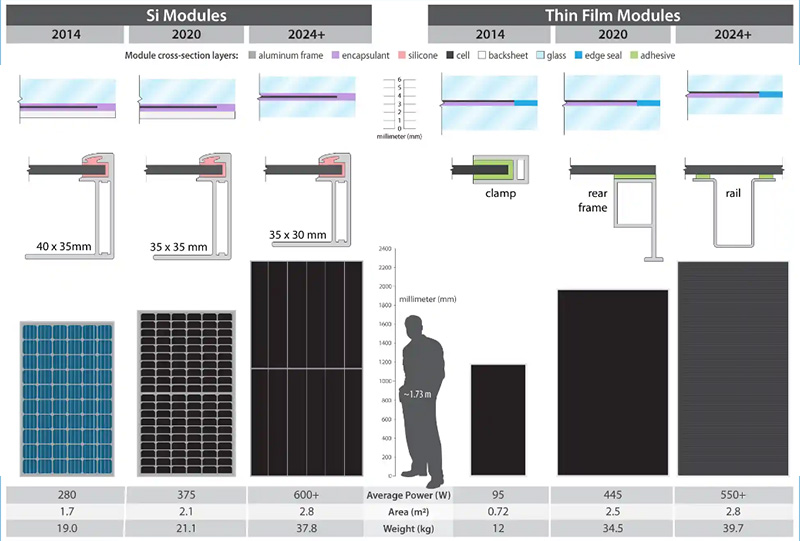

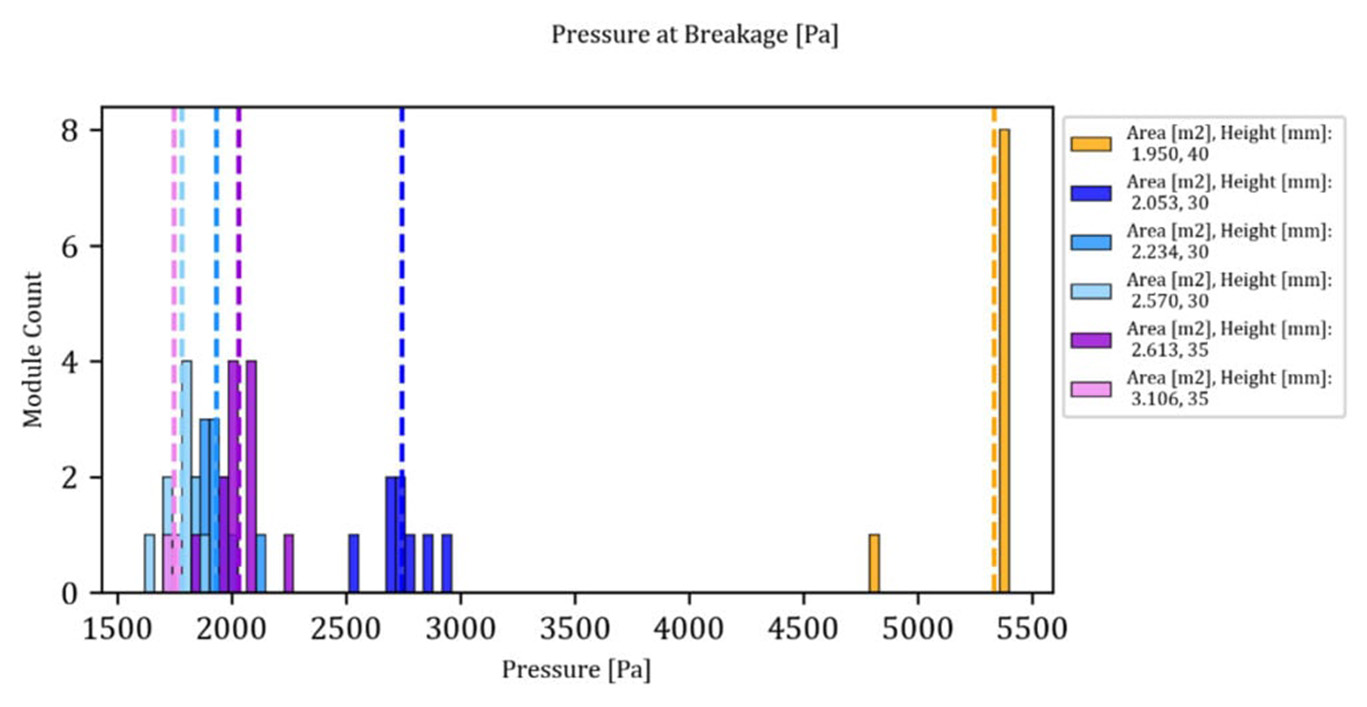

Since the trend toward larger modules began in 2020, module sizes have rapidly increased, meaning each module must withstand greater pressure. However, to make matters worse, material usage for larger modules has not increased but decreased:

• Glass thickness: reduced from 3.5 mm to 2 mm

• Aluminum frame height: reduced from 40 mm to 30 mm

• Aluminum frame thickness: reduced from 2 mm to 1.2 mm

▽ As the component size increases, the material usage decreases

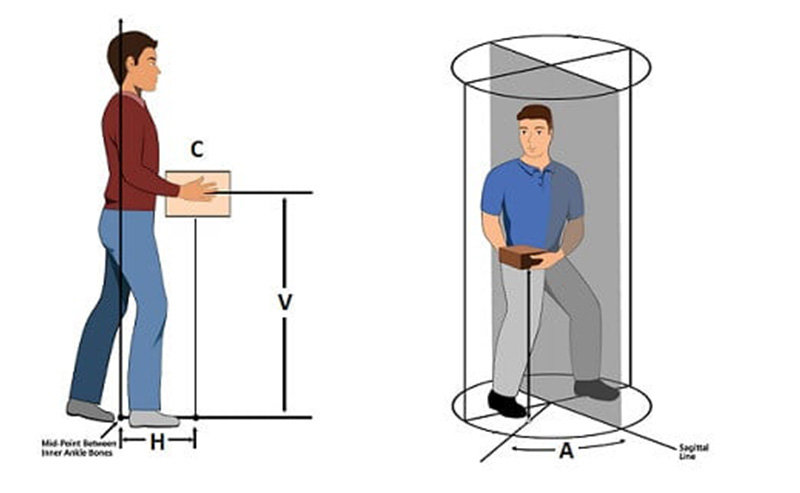

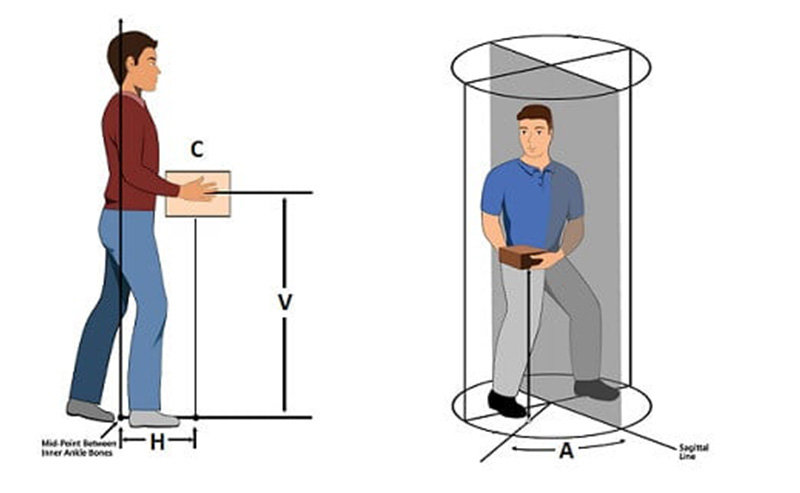

While reducing material usage helps decrease the overall weight of modules, speeding up installation, it also raises concerns. According to the National Institute for Occupational Safety and Health (NIOSH), the maximum recommended weight for two-person lifting every five minutes is 33.5 kg.

Clearly, if material usage from the single-glass module era were maintained, many modules would far exceed this weight limit.

▽ NIOSH has strict regulations on artificially lifted weights

▽ NIOSH has strict regulations on artificially lifted weights

Of course, it is widely understood that the primary goal of reducing material usage is cost reduction.

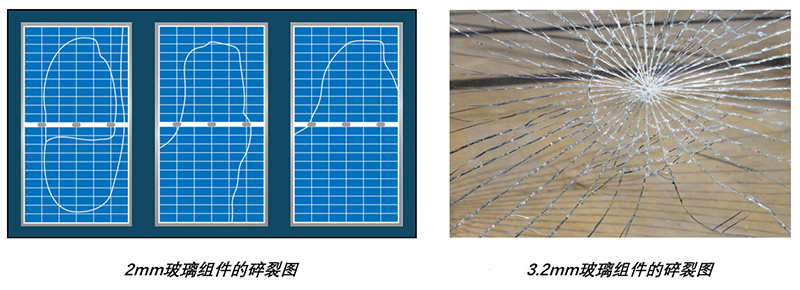

However, cost reduction has inadvertently led to lower quality control. The complexity of producing 2 mm glass is nearing the ceiling of glass manufacturing technology, making quality control far more challenging than for 3.2 mm glass.

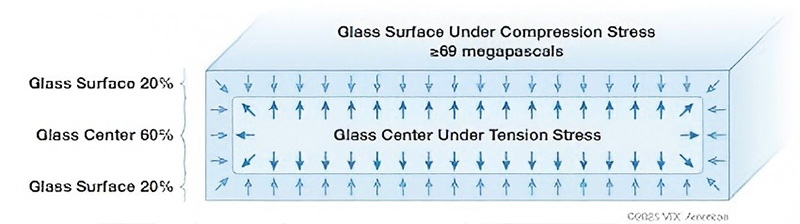

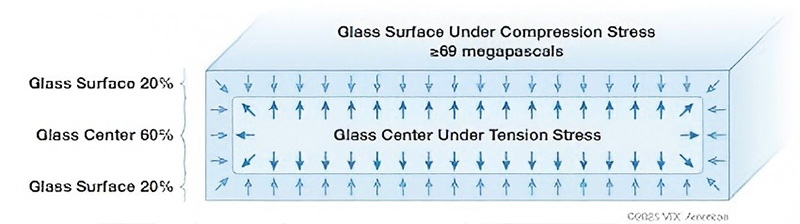

To enhance shatter resistance, PV module glass often undergoes thermal and chemical treatments. The strength of the glass largely depends on this treated, reinforced surface layer, which typically accounts for 40% of the glass thickness.

During the 3.2 mm era, manufacturing processes could effectively create this protective layer. However, maintaining the same protective layer thickness in the 2 mm era has become exceptionally difficult.

▽ The protective layer on the surface of the component generally accounts for 40% of the total thickness

▽ The protective layer on the surface of the component generally accounts for 40% of the total thickness

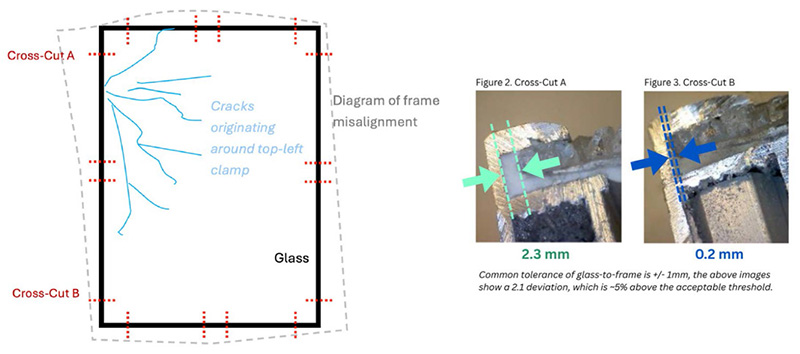

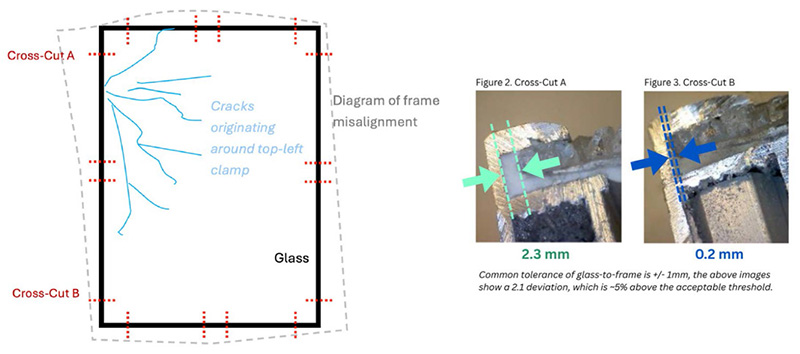

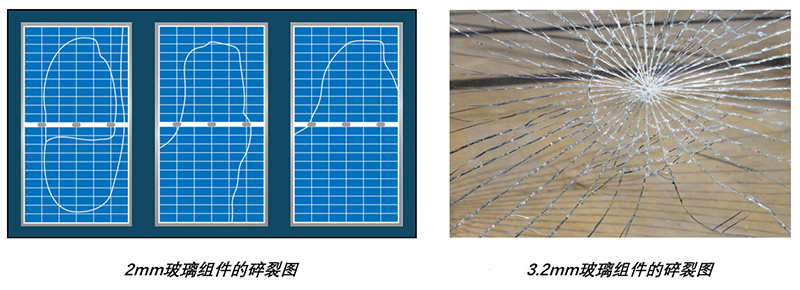

Now, the breakage patterns of thick and thin glass in the field have fundamentally changed. Previously, 3.2 mm glass breakage often appeared as "center cracking," making it easier to trace the failure point. In contrast, 2 mm glass failure cracks appear randomly, making it extremely difficult to identify the cause of failure.

▽ The differences in the production process of component frames also affect the mechanical properties of the components

This complicates the implementation of effective corrective measures when modules are damaged. Even if modules are replaced, similar damage may recur.

▽ The situation of component glass shattering has changed

Chapter 3: Single Testing

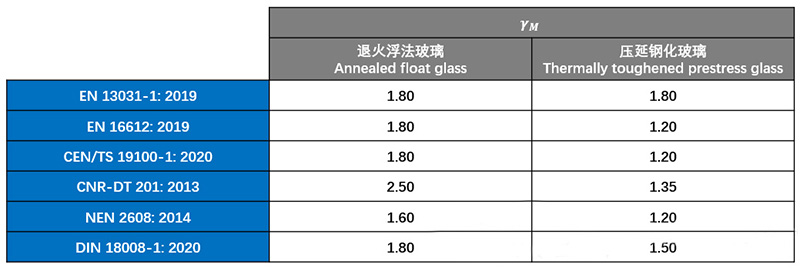

Behind the phenomenon of module breakage at project sites, another critical factor cannot be ignored. When module manufacturers specify mechanical performance, they often rely on the test requirements of the IEC 61215 standard. IEC provides a comprehensive testing protocol and specifies a test safety factor: r_m = 1.5.

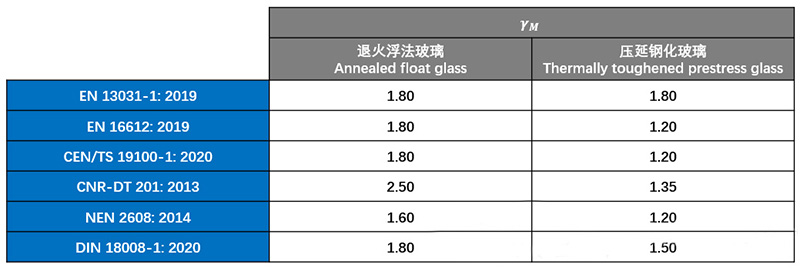

This cave once wrote a special article titled "Test Loads & Design Loads: How to Match Project Requirements?" The significance of this safety factor is also discussed in the text. The safety factors of glass produced by different processes are also not the same.

▽ The safety factors of different process glasses

This safety factor’s significance varies depending on the glass production process.Due to the inherent randomness and inconsistency in float glass production, the required safety margin is generally higher than for rolled glass. Currently, module manufacturers often opt for cheaper float glass for the rear glass of modules. As shown in the table, the safety factor for annealed float glass ranges from 1.6 to 2.5.

Thus, for material property safety margins, the 1.5 safety factor required by IEC is clearly insufficient.

But this is not the most alarming issue.

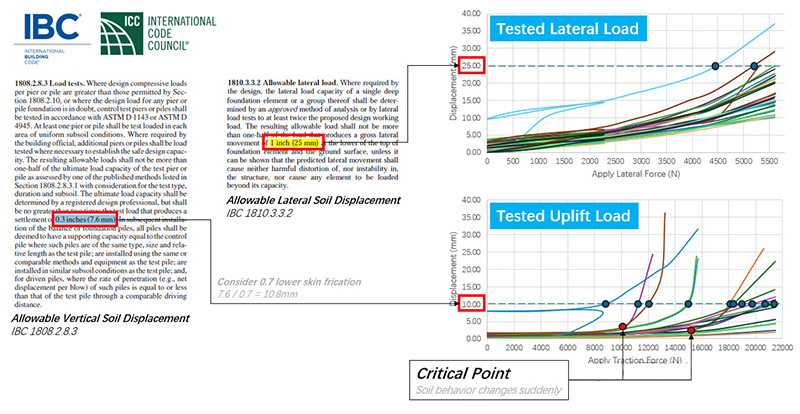

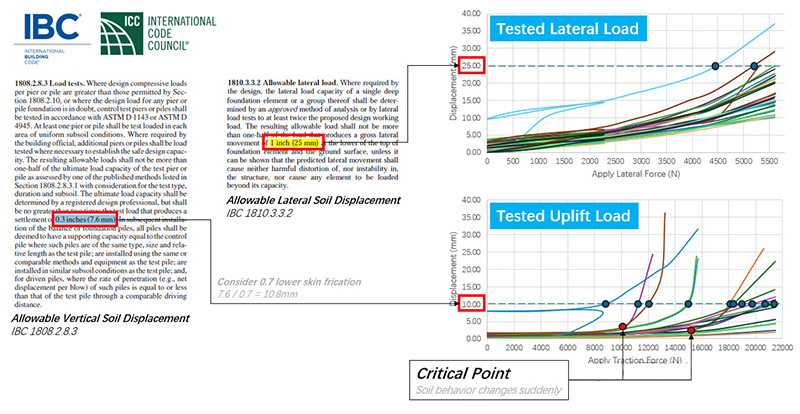

When designing projects, a module compatibility test is often conducted to determine whether a specific module matches the tracker structure. This test applies the project’s required loads to the module based on the actual tracker and module installation method. Passing this test is used to verify that the module meets project requirements.

At first glance, this process seems logical and compliant. However, it overlooks a critical issue: all tests are conducted only once. Whether for small kW-scale projects or large GW-scale projects, the reliability of millions of modules in a power plant hinges on a single sandbag test.

▽ The fate of the entire photovoltaic power station lies in a single component test

It is important to note that even for modules of the same model, structural characteristics can vary due to different production batches. This means each module is unique, and testing a single module cannot comprehensively and accurately reflect the true condition of all modules.

Module load testing is similar to structural testing. In the structural industry, obtaining accurate structural characteristics typically requires extensive repetitive destructive testing (test-to-failure). This approach accumulates reliable data to form a stable sample.

▽ For instance, in POT testing, multiple samples are often required and the failure limit is repeatedly measured

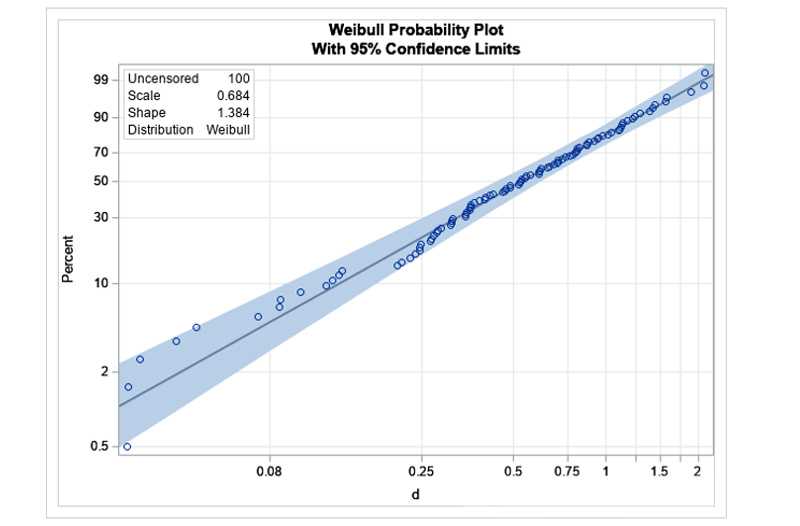

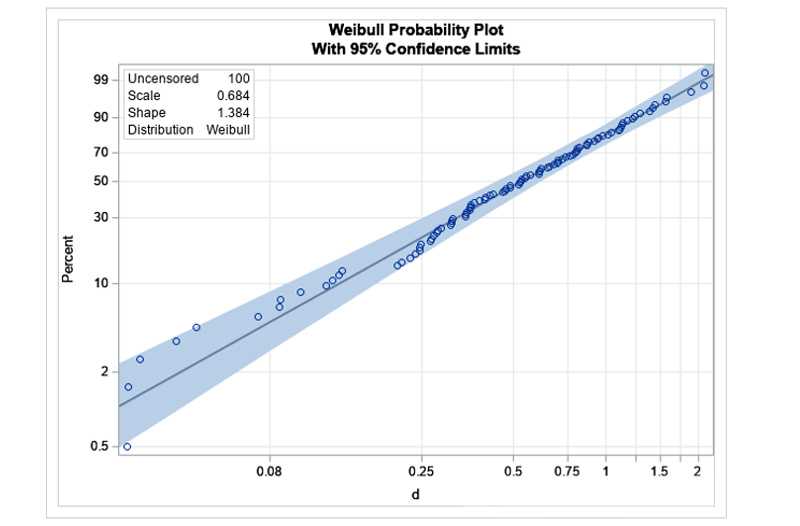

It is worth noting that such destructive testing requires a specific sample size, usually 25–50 modules per sample group. Based on this large sample data, a Weibull probability distribution model can be constructed, and statistical analysis can derive the coefficient of variation. Finally, this coefficient of variation can be used to calculate the safety factor corresponding to material uncertainty.

▽ In statistics, the Weibull distribution is often used to determine the probability of product failure

Chapter 4: Path to Solutions

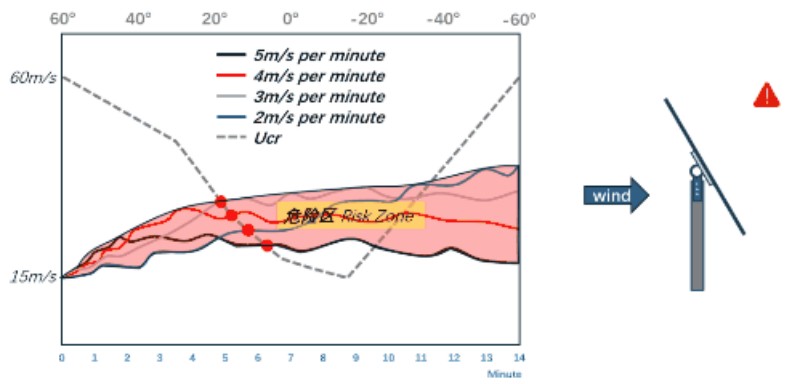

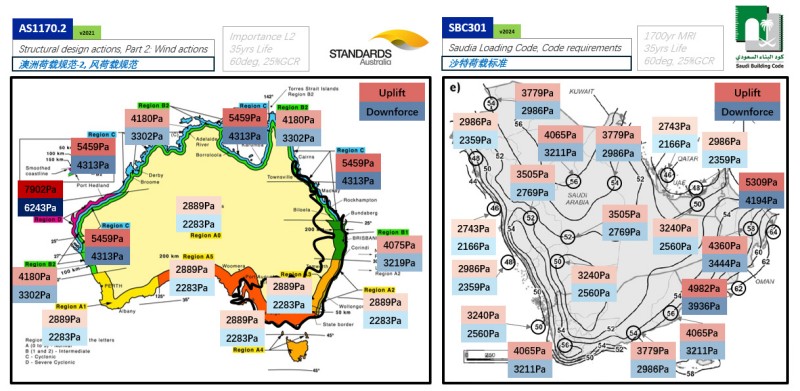

This article focuses on the long-term trend in the PV industry: cost reduction and efficiency improvement. Cost reduction is not limited to modules; under immense cost pressures, other system equipment is also exploring optimal cost-reduction paths. However, when various equipment manufacturers’ "new technologies" are applied at the system level, they inadvertently increase the risk of module breakage.

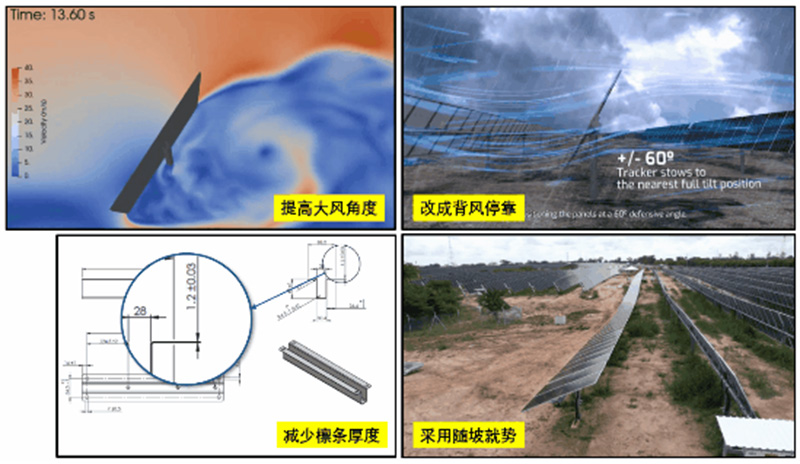

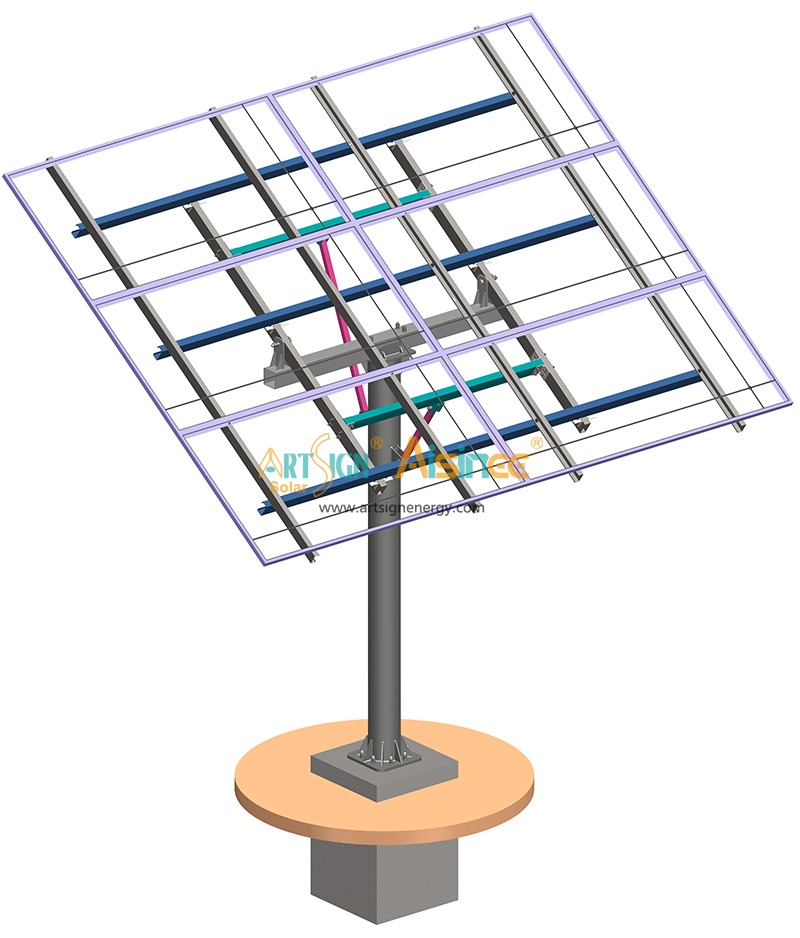

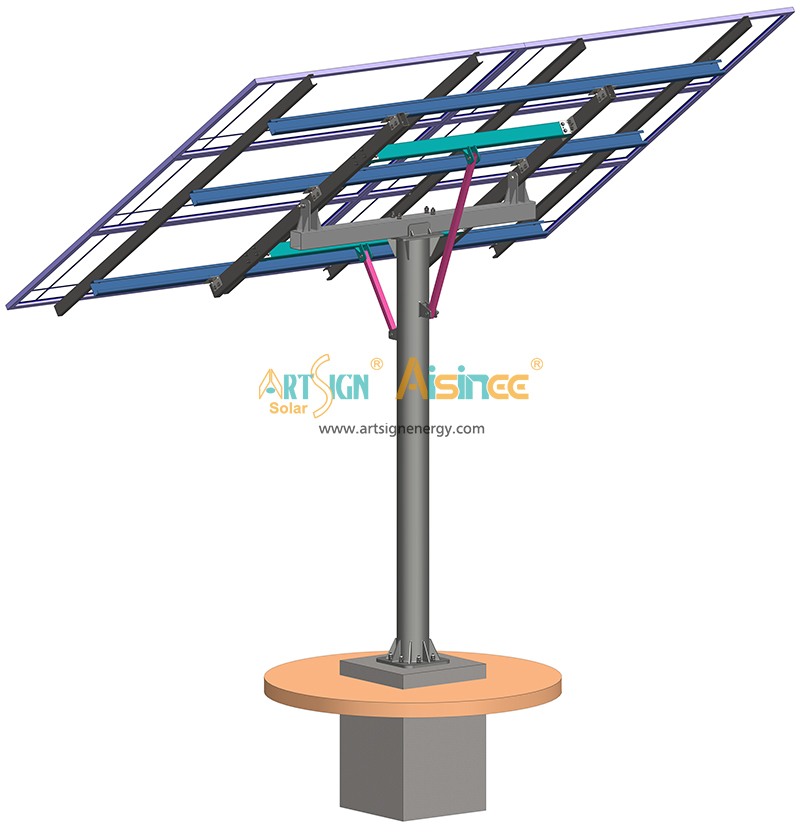

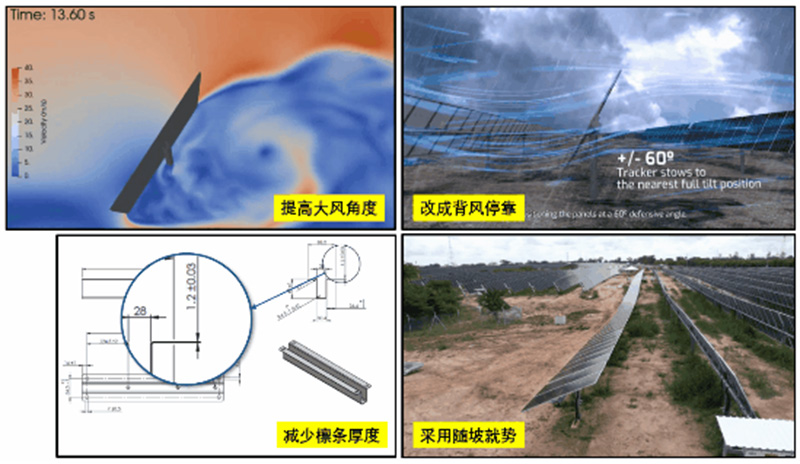

Common cost-reduction measures for tracker manufacturers include:

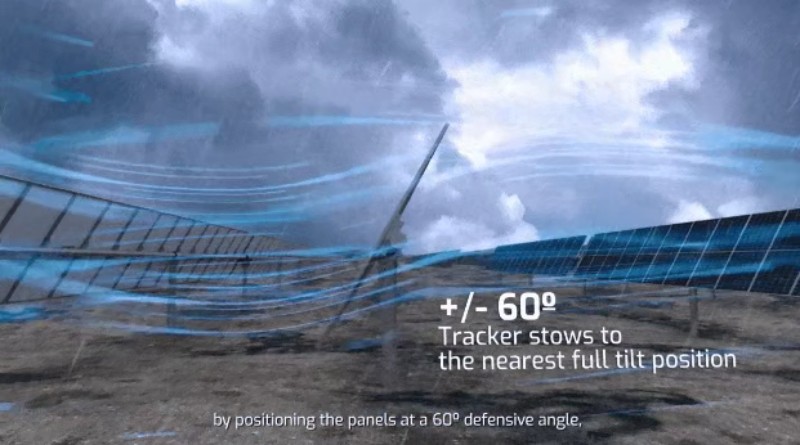

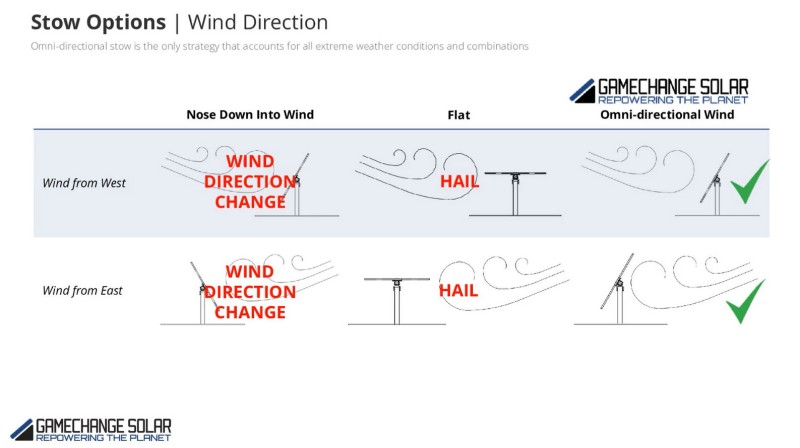

• Increasing the stow angle from 30° to 60°

• Reducing purlin thickness from 2 mm to 1.2 mm

• Increasing column spacing from 7 m to 10 m

• Switching from windward stowing to leeward stowing

• Adapting to terrain by bending the main shaft and modules to reduce earthwork

Due to industry barriers, collaboration between module and tracker manufacturers is challenging. The result is each party reducing its own costs while shifting the ultimate risk to system users.

▽ Trackers are also adopting various "new technologies" to reduce costs

However, not everyone chooses to "bury their head in the sand." Increasingly, people are actively exploring solutions and proposing various creative ideas.

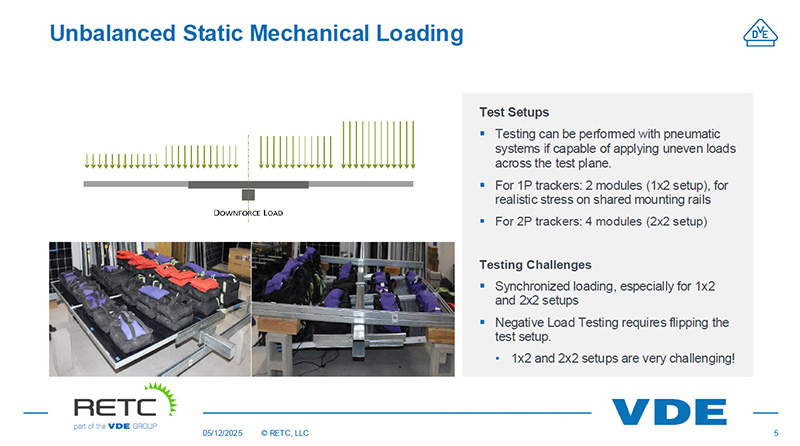

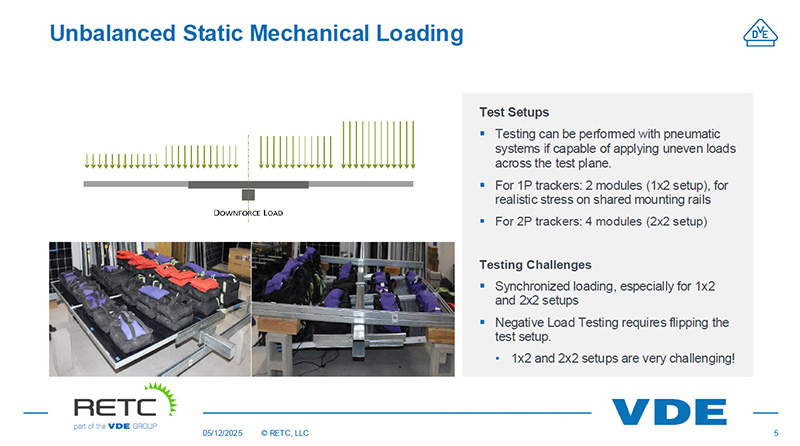

▽ VDE proposes unbalanced component testing

▽ Steel frames can effectively enhance the pressure resistance capacity of components

▽ The component recycling industry has also quietly emerged

▽ The general process of component recycling

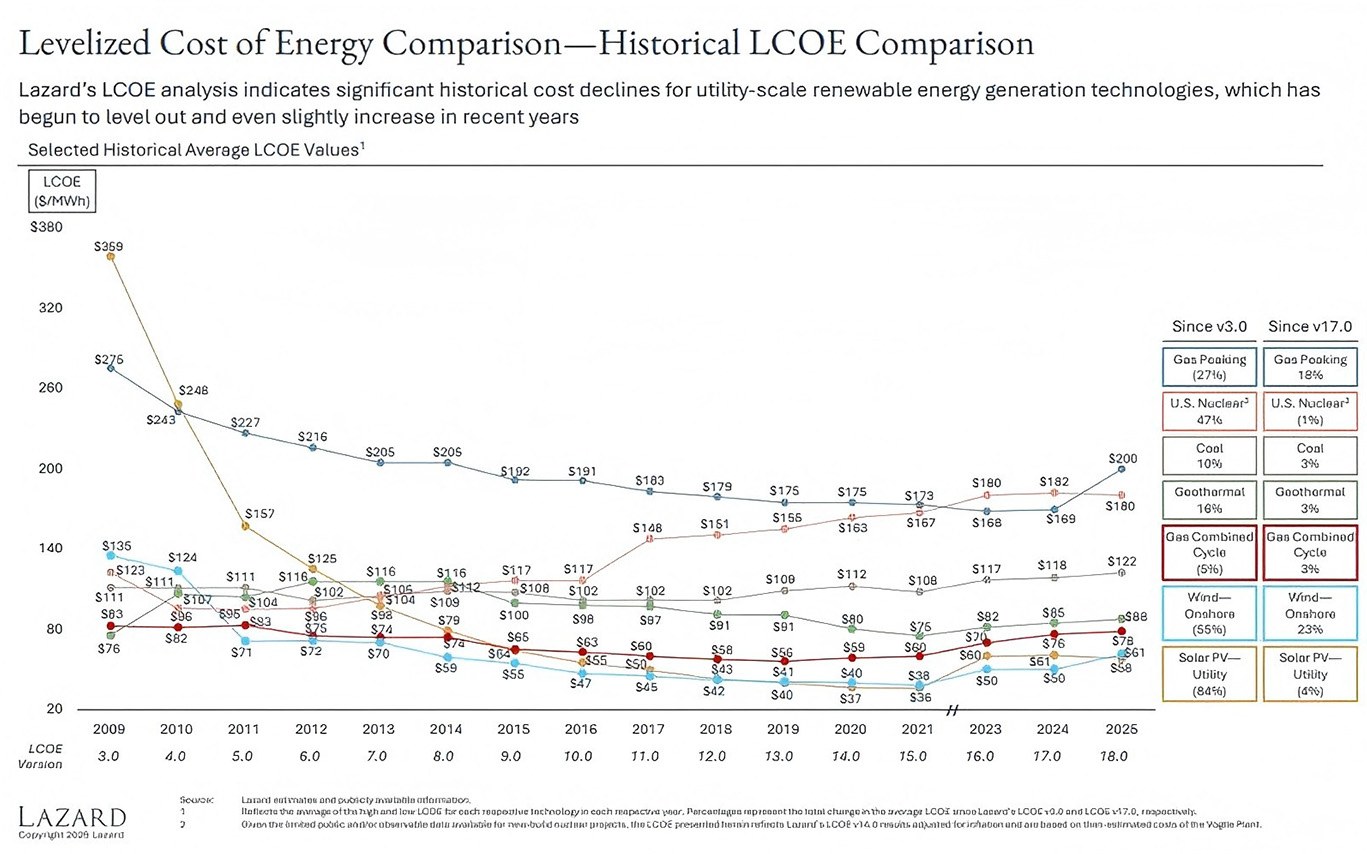

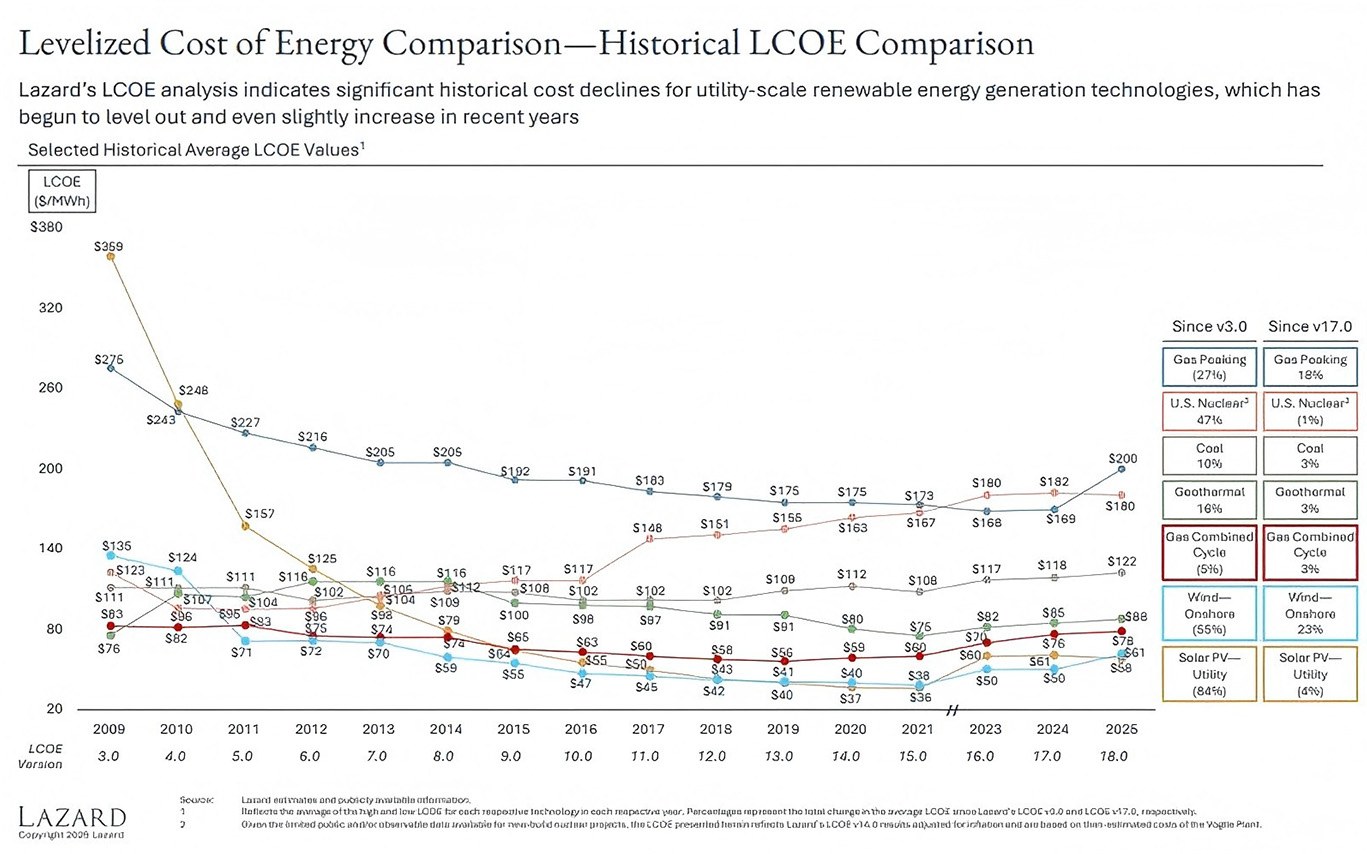

In 2025, thanks to collective efforts, the cost of PV power generation has reached a historic low. Among various power generation methods, PV has become the undisputed leader in LCOE (Levelized Cost of Electricity).

▽ Photovoltaic power has become the most cost-effective energy source for power generation

This achievement is inseparable from every individual reading this article. Let us work together to break industry barriers, face challenges, and embrace greater opportunities of the era.